Features:

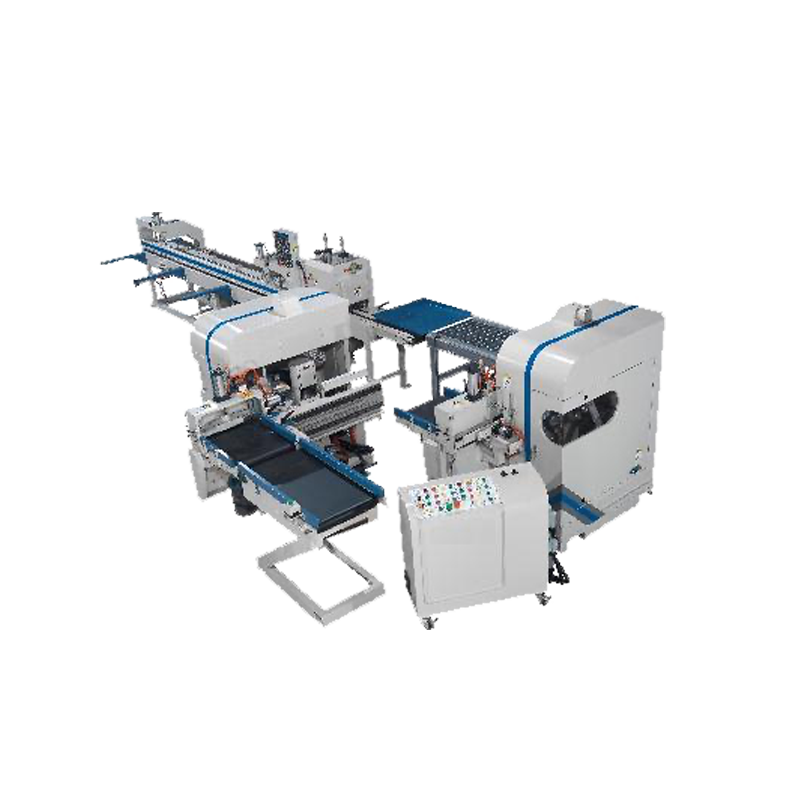

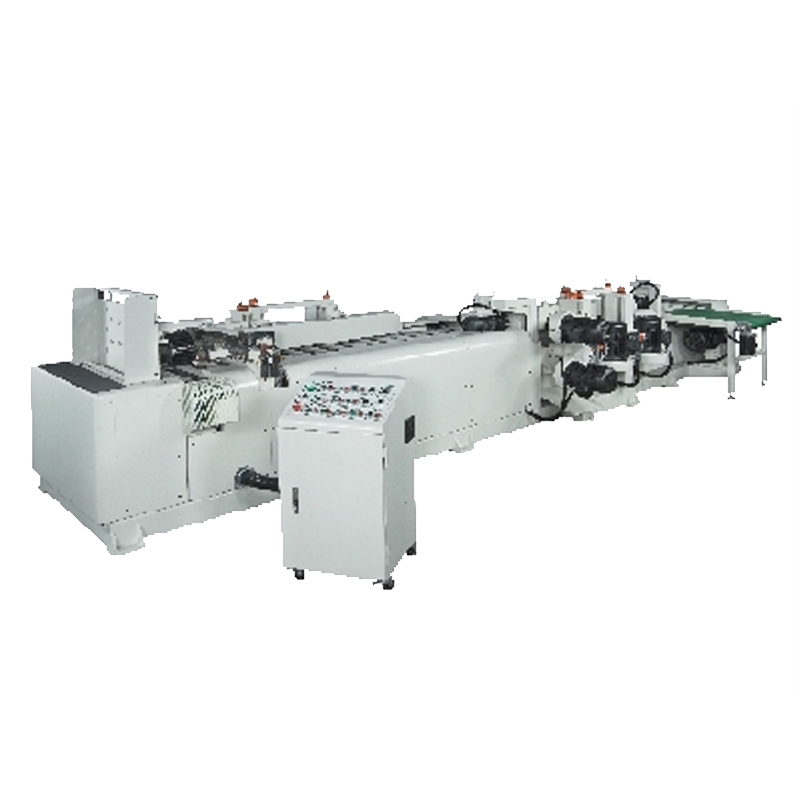

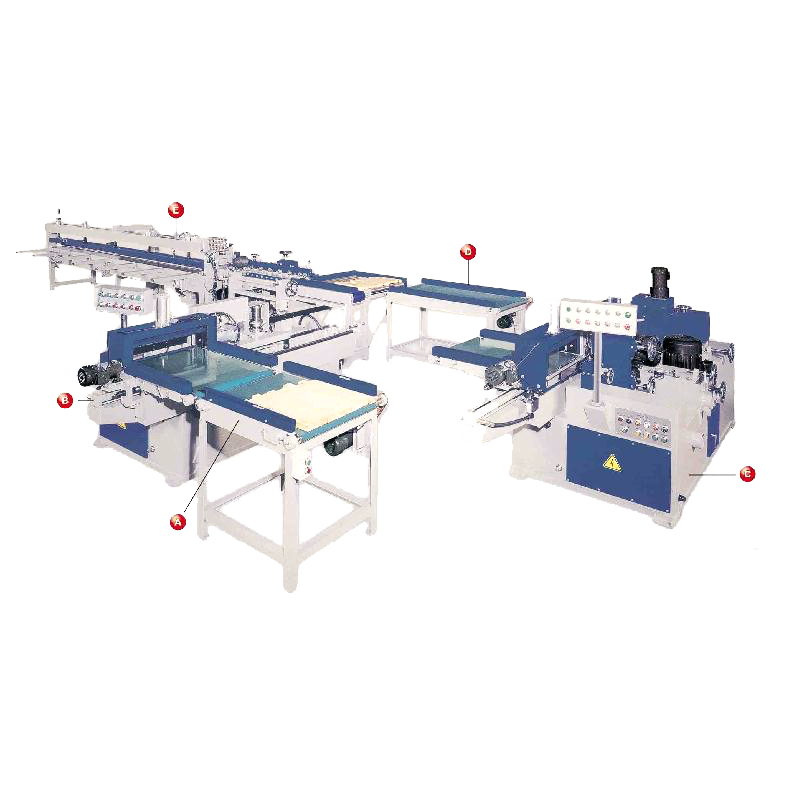

- The fully automatic finger joint production line complete with the right hand shaper, left hand shaper, and assembler to produce the mass finger joint stocks.

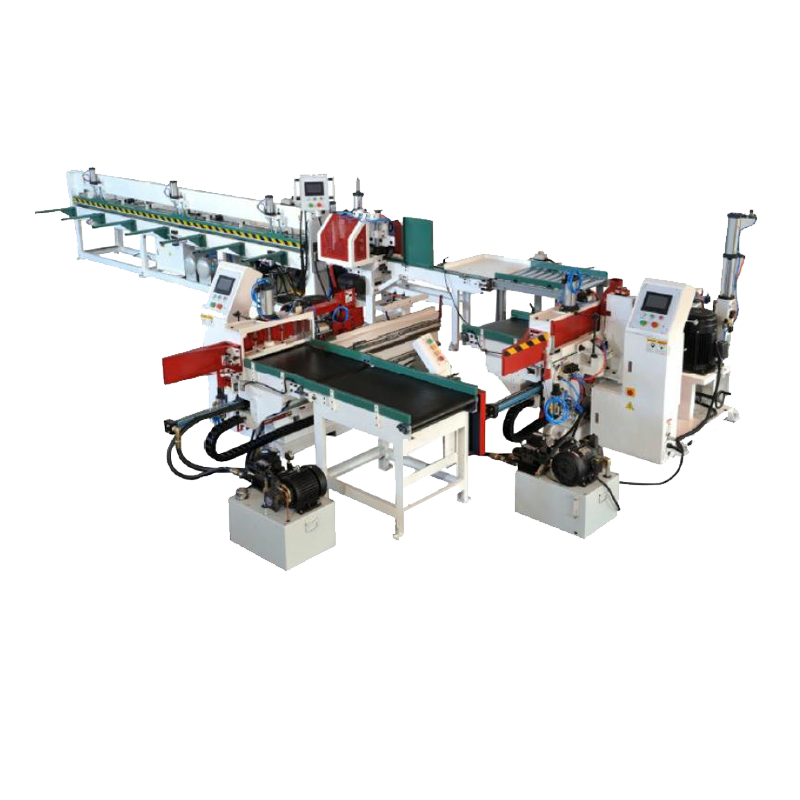

- The right hand shaper performs end trimming and shaping functions on right end of sticks.

- The left hand shaper performs end trimming, shaping & gluing functions on left end of sticks.

- The two trim saws are fitted with one saw blade for cutting even end of stick, and one blade for tip break ensuring a great jointing result.

- Air-operated clamp comes down to hold sticks firmly in place. After workpiece is clamped, table starts to feed, performs trimming and shaping operations.

- The shaper spindle is precision-constructed for cutting finger shapes accurately and accommodates a maximum cutter diameter up to 6".

- The spindle height adjustment is displayed on a dial readout gauge for easy adjustment.

- The table travels on a precision linear motion guide.

- The table traverse is driven by hydraulic power system, ensuring very stable, smooth workpiece feeding. Thus, an accurate, fine cutting result is guaranteed.

- Once the right hand shaper finishes the cutting, then the conveyor table automatically transfers the sticks to the left hand shaper and comes back to the start position for acceptance of the new sticks for work right away.

- In the meantime, when the left hand shaper finishes, the sticks will auto transfer for inspection, then be sent to assembler for assembly press to finish the cycle.

- The assembler is a very efficient automatic machine that performs three functions, jointing of sectional sticks which have been glued, cutting the jointed sticks to desired length, final assembly is securely pressed by powerful hydraulic system, then the jointed sticks are fed out regularly.

- Auto power feeder for fast feeding and auto stops at the length to be cut.

- Furnished with cutting off saw as standard equipment for cutting workpieces to the length desired.

- The maximum length of jointed stick is 16'. Other sizes are available upon request.

- The machine employs an advanced programmable logic controller for easy operation and maintenance.

- The machine's motion sequences are displayed by the signal lamps for easy checking in the event of a malfunction.

Specification:

L5-46

- Table size W420-460mm,H15-75mm L150-600mm

- Conveyor motor 0.375Kw (1:10)

- Moving carrige HP 0.75Kw(1:10)

- Figer jointer shaper HP 7.5 Kw

- Saw blade HP 3.75Kw

- Cycle speed 2-5/min

- Gluespreader system

R5-46

- Table size W420-460mm,H15-75mm,L150-600mm

- Conveyor motor 0.375Kw(1:10)

- Moving carrige HP 0.75Kw(1:10)

- Figer jointer shaper HP 7.5Kw

- Saw blade HP 3.75Kw

- Cycle speed : 2-5/min

Z-46

- Table size W460xL890mm

- Conveyor motor 0.375Kw(1:10)

FJ-36

- Working dimension L3600xW75xT75mm

- Motor of hydraulic pump 3.75 Kw

- Motor of cut-off saw 3.75Kw

- Conveyor motor 0.75Kw (1:15)

- Up/down in feed roller HP 0.75Kw(1:15)x2

- Inverter 3.75Kw

Related Products

-

4"x141" Auto Finger Jointer System

SFJ-4-141-AUTO $0.00 -

Auto Random Length End Matcher

SFJ-800AUTO $89,900.00 -

6"x244" Auto Finger Joint Production Line

SFJ-6-244-AUTO $89,900.00 -

6"x244" Auto Finger Joint Production Line

SFJ-6-244-AUTO $89,900.00